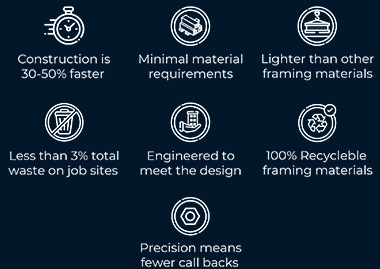

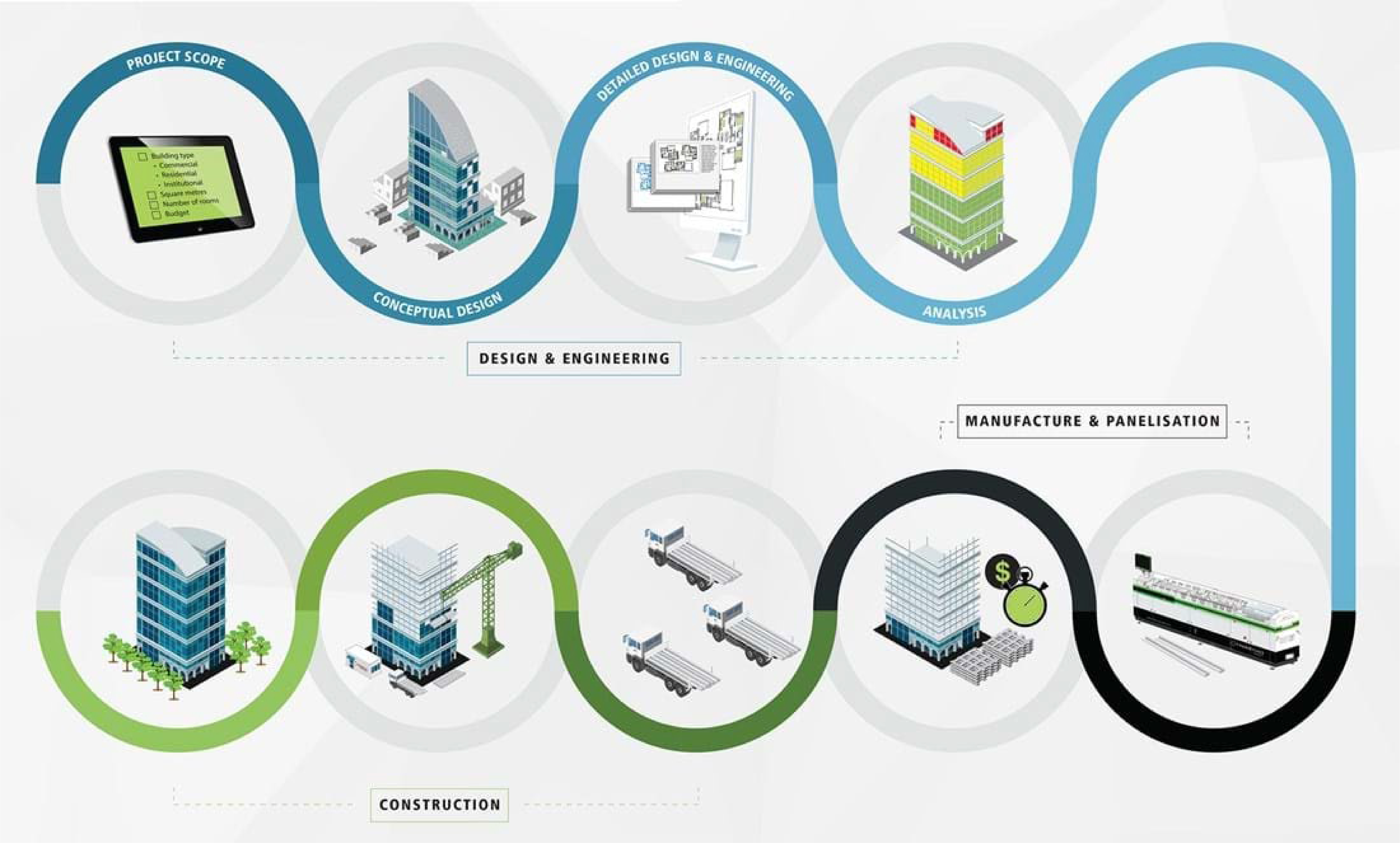

Intellisteel has chosen the world’s most advanced, end-to-end, steel frame design, manufacturing, and software technology to power its mobile factories and factory machines. Each manufacturing methodology delivers practical solutions to historical, current, and future gaps found in traditional construction that streamline the entire steel frame design & build process, slashing production time and delivering the highest quality product available.

Behind Intellisteel’s On-Site precision, design-build mobile factory solution is a ground- breaking combination of the industry’s leading computer-aided engineering software and production equipment together with the industry’s fastest framing solution available.