As construction demands soar, and so do the cost of materials, owners and developers are seeking ways to lower costs without sacrificing quality. In the past, wood was the prominent building material, as it was readily available and research into the environmental impact of using this natural resource was non-existent. However, modern times have cast a powerful light on the timber industry, showing up to seven billion trees are lost to deforestation every year in support of the traditional construction building practices.

Today, more and more companies are turning to alternative construction materials to help mitigate these astonishing numbers and lower our impact on the planet’s limited natural resources. Of those alternate materials, one has quickly made its way to the top, standing apart from the rest for its superior qualities, and that is – cold formed steel (CFS). Steel is not only environmentally friendly but also durable and cost-effective, making it the true “VIP” and preferred material of the construction industry.

What is the CFS advantage and how can you benefit from it?

This material is considered the most important construction and engineering material, being used in a wide variety of products from cars and refrigerators to cargo ships and buildings and everything in between. This form of construction boasts the lowest amount of carbon emissions and waste which has a positive ripple effect on neighboring resources. CFS is now, widely considered the clear choice for the future of construction as we move into a more environmentally progressive world.

Whether being used for a large or small project, steel ensures the structure will last for years to come. It is considered the premier material for utmost safety and durability for structural framing foundations. With its highest strength-to-weight ratio of any construction material available, it delivers superior structural integrity with less material and less weight, thus reducing cost, labor, and schedule. It is a low-maintenance resource and long-lasting material that will ultimately lead to less repairs and carbon emissions.

Reduced Energy Cost

Steel has the advantage of being easily insulated, which lowers energy bills and saves money. When we use less energy, it not only positively affects our cost of living prices, but helps the environment.

These energy savings translates into how quickly projects can be erected, thus saving in waste for the entire timeline of the construction process. Using steel can significantly increase construction speed, up to 50% faster than wood and 50% faster than concrete. By increasing construction speeds, companies can save energy, which in turn, saves money. These savings are passed down to the consumer, decreasing their wait time to enter their newly constructed building and helping to avoid extra expenditures.

Lower Environmental Impact

There are many reasons steel is an excellent construction material, but one of the most important is its reduced impact on the environment. The deforestation sector accounts for a staggering amount of the earth’s carbon emissions, accounting for up to 10% of all emissions released into the atmosphere. This high carbon release not only comes from the pollutants emitted from the vehicles used to tear down the trees, but it’s also due to the high carbon concentration released when the trees die. Forests are vital carbon sinks, which means they absorb the carbon dioxide in the earth’s atmosphere and emit clean air. However, when they are cut down during deforestation, the carbon stored within each tree is released back into the air, increasing emissions at an alarming rate.

By eliminating deforestation, we can help slow the incoming climate crisis, but to do that, we must make the switch from using wood as a primary building material to a more sustainable and environmentally friendly, infinitely recyclable option like steel. Steel uses significantly less energy and causes lower emissions than wood and involves using recycled metals in its production. Additionally, steel lasts significantly longer than wood, reducing the need for replacement materials down the line.

Resists the Elements

Steel has the added benefit of being an incredibly durable material, allowing it to withstand severe weather. Natural disasters like earthquakes, fire, flooding, hurricanes, and seasonal pest control can significantly impact the livelihood of buildings constructed with traditional wood material.

At Intellisteel, we have seen it first hand.

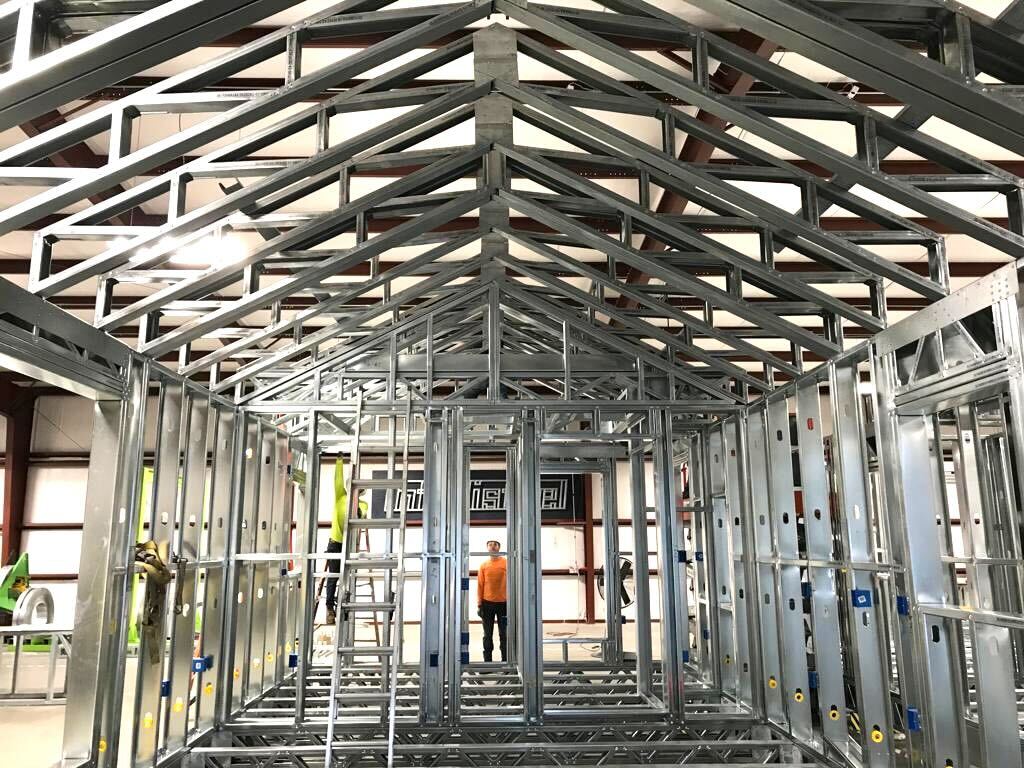

When one of the most devastating disasters, Hurricane Dorian, came ripping through the Caribbean islands, Intellisteel provided future safety through humanitarian efforts of several established foundations for the residents of the Abaco Islands in the Bahamas. We re-built entire structures in these communities that were designed to withstand winds up to 220 mph. We manufactured and pre-panelized the entire structures Off-Site then shipped these pre-fabricated steel paneling structures to residential homes, hurricane shelters, and primary schools to help rebuild the island, and protect its residents and children against future disasters. In the image below, you can see our work as we begin to rebuild the community.

As we see severe climate changes approaching, we sit at the forefront of providing alternative ways to offer superior protection against hurricanes, tornadoes, snowstorms, flooding, and earthquakes, making them an all-season, every climate challenge solution. For example, in earthquake-prone areas, steel is certified as the safest building material to use, thanks to its light weight, material resiliency and flexibility as compared to concrete and wood. Effectively insulating steel against extreme temperatures.

Reduced Waste

Steel production uses far less waste than other building materials, as many companies manufacture their products to order. The ability to produce strictly the amount of product necessary for a project eliminates excess manufacturing emissions, waste from leftover materials, and unnecessary gas consumption from transporting heavier than needed loads. Approximately 30% of the construction materials on a typical project site are unused and wasted, resulting in around 145 million tons of new waste entering our landfills every year. Using steel as a customizable material not only reduces waste but any product that isn’t used is easily recycled and repurposed. It’s easy to see how using steel is the best choice for the environment and the consumer.

Take it from us. The picture below is an example of a day’s worth of waste in these two bins. During the fabrication process, these scraps are created when each individual component is cut to length, fastener holes are pre-punched and swaged, pre-notched and prepared for assembly. The leftover steel is then collected to recycle. We are mindful and deliberate about how we deal with our waste while we are On or Off-site, thus creating a completely sustainable construction environment and eco-friendly process not found with any other traditional construction material, means, or method.

Cost Effectiveness

When using a company that fabricates its steel to order, it significantly reduces overhead costs, passing the savings down to the consumer. Steel’s long lifespan eliminates the need for replacement or reconstruction down the line, which saves considerable money in the long term. Additionally, with the ability to use recycled materials in the manufacturing process, steel costs remain lower than many other materials, holding its value against extreme market volatility. When using steel as the primary building material, the structure can withstand greater weather phenomena, reducing the cost of repairs, building maintenance and from severe weather incidents. All of these examples add up to money saved, making steel the superior, cost-effective choice.

Design Flexibility

Companies like Intellisteel, utilizing On-Site precision manufacturing equipment have unprecedented design flexibility. Unlike other construction materials like wood, CFS studs, beams, walls, trusses, joists, and headers can be formed as needed, enabling the architect to make last-minute changes to the structure without incurring additional time and costs. This unique flexibility opens many construction possibilities, mitigating the time and cost associated with unexpected issues encountered during construction.

There’s truly no comparison when reviewing the benefits of steel over other building materials. Steel stands apart from the rest as the exceptional option for all your framing needs. Once you’ve decided to use steel as your material of choice, finding the right firm who can provide engineering and design for your project’s superstructure framing is vital. You want to ensure you choose a company with the knowledge and expertise to provide you with the highest quality product available. Intellisteel is a structural design, engineering, and manufacturing firm that delivers the most optimized use of material for virtually any type of project.

The Revolution in Steel Framing

When you choose Intellisteel, you open the door to unprecedented architectural design freedom, turning your inspiration into reality faster than you ever imagined possible. Through the use of their 100% engineered and customized steel framing On or Off-Site manufacturing, you can create the structures you imagined anywhere while maintaining lower cost to build, faster than traditional schedules all while exceeding any level of sustainability standards.

Don’t settle for inferior building materials like wood that harm the environment and present fewer long-term benefits. Steel is the superior choice for structures that are built to last and help protect the future health of our planet. Intellisteel is the revolutionary structural design, engineering, and manufacturing firm you need to ensure your structures last a lifetime and beyond.